Featured Offerings

Pavement Marking

Keenline Innovation Technology and Training creates and reviews marking programs used throughout the municipality. We also develop and monitor paving marking material selection and inventory programs.

Read MoreHighway Signs

Keenline Innovation Technology and Training ensures that new sign installations meet manufacturer’s material specification for reflectivity values. We also create a sign inventory with GPS documented locations, reflective sheeting type, sign and sign structure condition, and more with any deficiencies noted.

Read MoreRetro-Reflectivity Measurements Pavement Marking

We determine when remarking is required with the use of a specialized tools called retroreflectometers. We also ensure that you are achieving sufficient glass beads in your pavement markings, and that they have been properly embedded.

Read MoreCurve Analysis

We review curves using CARS program from Rieker Inc. We determine a safe advisory speed for curves, proper signage and placement, as well as the curve radius, super elevation and vertical profile.

Read MoreProduct Evaluation

At Keenline Innovation Technology and Training, we monitor and evaluate the application of materials on Provincial and Municipal traffic paint test decks. We then assemble the information gathered for use by Municipalities in determining the best product to be used to increase the lifespan of their pavement markings.

Read MoreRetro-Reflectivity Measurements Roadway Signs

We are equipped with a hand held sign reflectometer with built in GPS and barcode reader. This specialized instrument allows us to measure all types of retroreflective materials with a single measurement.

Read More

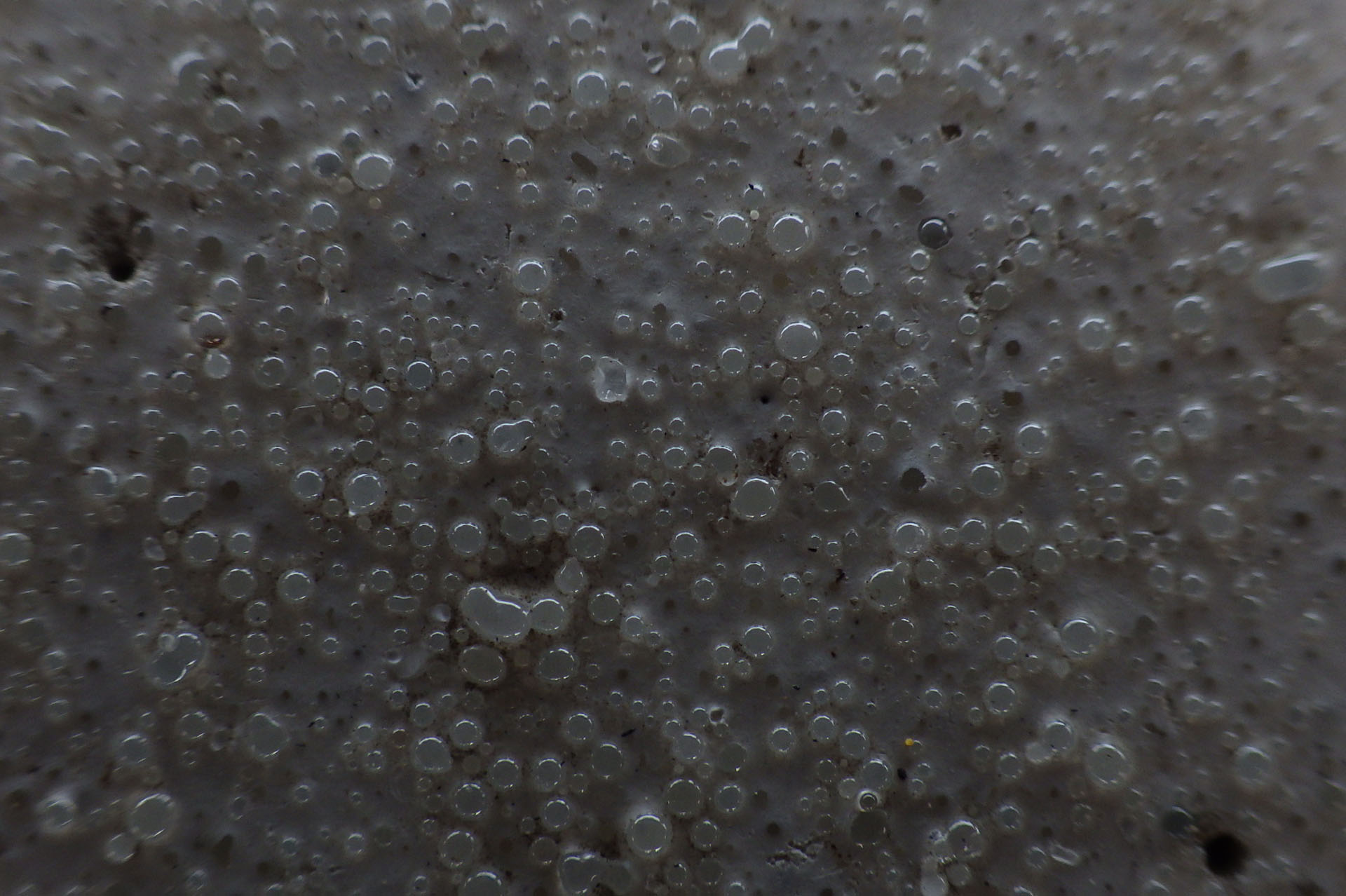

Glass Bead Application Inspection

Inspection of pavement markings during application involves the on-site inspection of the pavement marking during the striping operation. This inspection includes measuring the thickness, width, color, bead dispersion and depth, and nighttime appearance. Inspection during application is important because it allows for problems to be fixed immediately, greatly benefiting all involved.

Glass Bead Application Inspection

Inspection of pavement markings during application involves the on-site inspection of the pavement marking during the striping operation. This inspection includes measuring the thickness, width, color, bead dispersion and depth, and nighttime appearance. Inspection during application is important because it allows for problems to be fixed immediately, greatly benefiting all involved.